MENU

The Most Trusted Water-Lubricated Bearings For Rotating Shaft Applications.

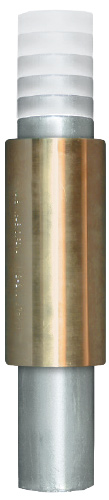

Duramax® Industrial Cutless® is the original true, Cutless® brand bearing. It is the one that has earned the trust of some of the largest OEM pump manufacturers in the industry. Cutless® has an extremely low coefficient of friction, unbelievable wear life, and protects the shaft from damage, even in heavily abrasive laden solution.

Other bearing companies have tried to copy the Cutless® brand, but none match our high quality standards and, most important, don’t have the experience to custom engineer our unique rubber polymer formulations.

Many new bearing products, including hard surface materials, have made performance claims. But, are still unable to reach performance records set by Duramax® Cutless® Industrial water-lubricated bearings.

Other bearing companies have tried to copy the Cutless® brand, but none match our high quality standards and, most important, don’t have the experience to custom engineer our unique rubber polymer formulations.

Many new bearing products, including hard surface materials, have made performance claims. But, are still unable to reach performance records set by Duramax® Cutless® Industrial water-lubricated bearings.

Duramax® Quality Control.

Cutless® bearings are engineered, manufactured and tested at our own facility, under the eyes of our dedicated, qualified bearing professionals. Every person on our staff has one mission, delivering the highest quality, dependable product and service, unmatched by anyone in the industry. We believe it’s the reason why Cutless® bearings continually out-perform other bearings.

Only bearing to meet all requirements of MIL-B-17901B Class II specifications.

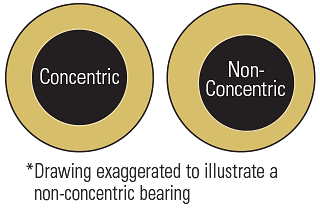

Optimal bearing concentricity eliminates uneven wear, vibration, and noise.

Every bearing is manufactured to tight industry tolerances.

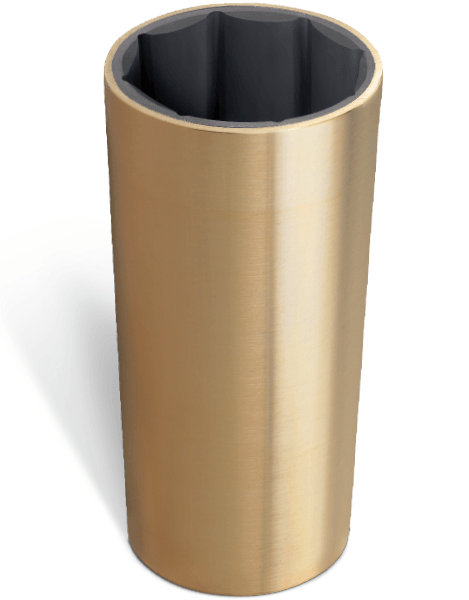

Custom-engineered, proprietary tough,  chemical and oil resistant polymer surface.

Permanently bonded to naval brass or non-metallic shell.

Bearings under 6” tested using “plug gages” to measure tolerances.

chemical and oil resistant polymer surface.

Permanently bonded to naval brass or non-metallic shell.

Bearings under 6” tested using “plug gages” to measure tolerances.

Duramax® Proprietary Rubber Polymer Compounds.

Rubber is proven to be an excellent hydrodynamic bearing material, with the presence of water. It dramatically reduces the coefficient of friction making it one of the most slippery surfaces available.

Every day our experts are custom engineering Cutless® rubber polymer formulations to improve performance for industrial applications, especially with abrasive laden solution. The results: tough innovative Cutless® elastomeric bearing compounds that provide maximum protection for both bearing and rotating shaft. We call it controlling “Total System Wear” (TSW). Unlike hard surface bearings that claim impressive life spans, but will cause scoring and excessive wear to the rotating shaft.

Whatever your application requires we will engineer the perfect liner formulation to be fully molded in a shell material that is custom manufactured for easy installation.

Every day our experts are custom engineering Cutless® rubber polymer formulations to improve performance for industrial applications, especially with abrasive laden solution. The results: tough innovative Cutless® elastomeric bearing compounds that provide maximum protection for both bearing and rotating shaft. We call it controlling “Total System Wear” (TSW). Unlike hard surface bearings that claim impressive life spans, but will cause scoring and excessive wear to the rotating shaft.

Whatever your application requires we will engineer the perfect liner formulation to be fully molded in a shell material that is custom manufactured for easy installation.

Duramax® Cutless® Innovative Design.

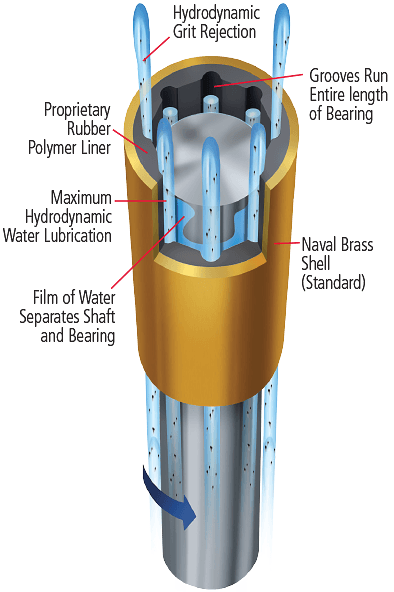

Cutless® “water-wedge” effect.

The rotating shaft and the rubber bearing lands are completely separated by a film of lubricating media during operation. A hydrodynamic pocket is formed in the rubber lands at a minimum journal speed of approximately 3.4 ft./sec. to establish a fully hydrodynamic film of lubricant, dramatically reducing friction and dissipating heat.

Cutless® “grit rejection”

In abrasive laden solutions the Cutless® bearing protects the shaft from damage and excessive wear. The elasticity of the rubber polymer lining allows the land’s surface to “deform”, protecting it from damaging grit particles. These abrasives are then rolled along the surface, until they are flushed out through lubrication grooves that run the entire length of the Cutless® bearing. Unlike non-rubber type bearings that retain and embed grit particles that can score the shaft and cause excessive damage.

View Photo Gallery

View Photo Gallery